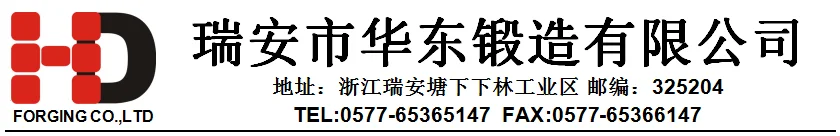

Etaining ring

The retaining ring of Forging Co., Ltd. is mainly used for axial fixation of parts on the shaft. The material of the retaining ring is 65Mn 60Si2MnA; the heat treatment of the retaining ring: d≦48, quenched and tempered HRC, 47-54 or HV470-580 , greater than 48, quenched and tempered HRC44-51 or HV435-530, the retaining ring needs to be elastically tested to meet the performance requirements of the product; install the retaining ring on the test shaft and keep it for 48 hours without breaking for toughness testing. For the retaining ring Specification design selection, if you want to add a polytetrafluoroethylene back-up ring to the static seal O-ring groove of the high-pressure oil cylinder, in general, the height of the back-up ring should be consistent with the depth of the groove, and the thickness of the back-up ring is 1~2mm, which can be extruded The situation determines itself. The radius of curvature of the groove is 0.8~1.6 times the diameter of the O-ring. Depending on the amount of compression, the fillet is less than 0.2.

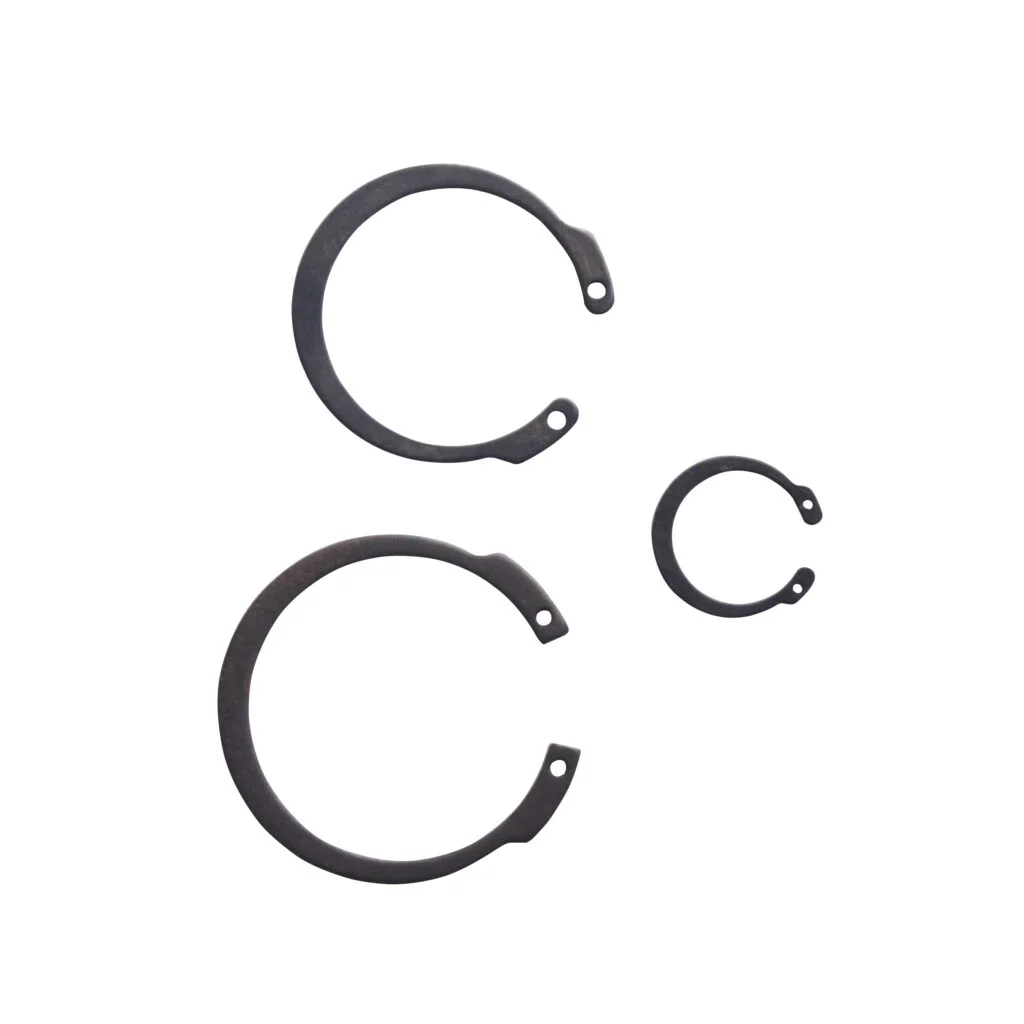

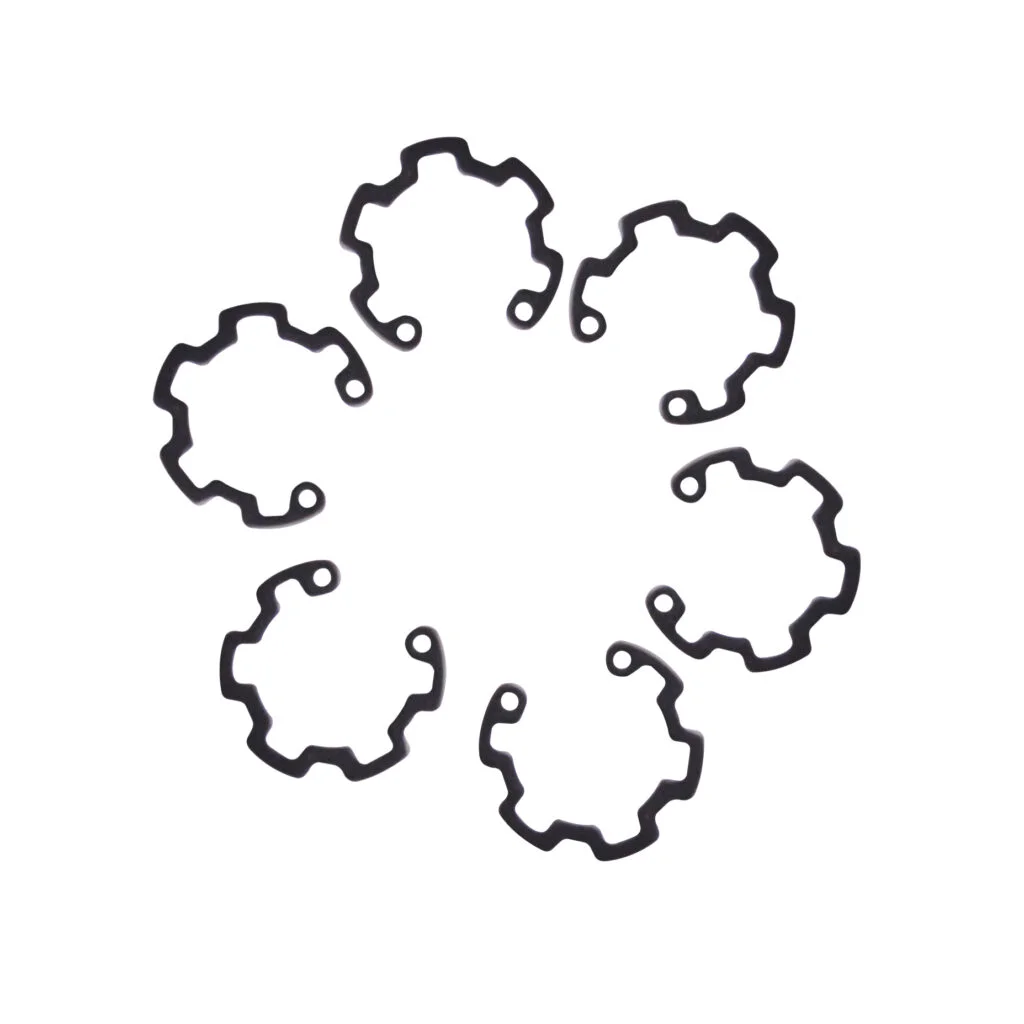

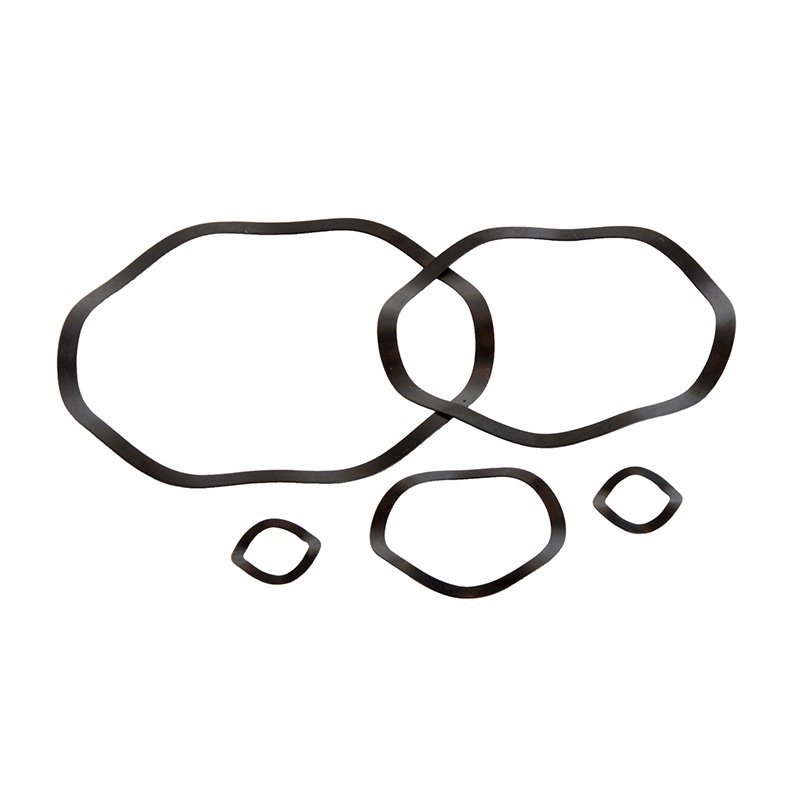

Wave washer

The wave washers of Forging Co., Ltd. are mainly used to prevent nuts (or bolts) from automatically loosening during mechanical design and production. Most of them are installed under the nuts to prevent the nuts from loosening. The commonly used wave washers are M3. , M4, M5, M6, M8, M10.M12, M14, M16, the materials are stainless steel and carbon steel, usually 65MN spring steel or 70# carbon steel, 3Cr13, stainless steel material SUS304 or SUS316 can also be used. The national standard for wave washers is GB/T 94.1-87. The standard stipulates standard wave washers with specifications of 2-48mm. 65Mn or some other low carbon steel, such as Q235, Q195, etc. The wave washer is shaped like a wave, is thin and elastic. Due to its shape characteristics and prevention function, the surface of the wave washer is free from defects such as defects, oxidation and rust. The surface requires oxidation and blackening treatment, and the waveform must be evenly distributed. , loading and accurate assembly in place.

Tow ball

A tow ball is also called a tow hook, a ball rear tow hook, a tow bar, a tow bar, etc. In a broad sense, a tow ball is a complete trailer system, which consists of three parts: a fixed bracket, a ball and a power harness (power control unit). The above three parts constitute a complete tow ball system.Our company produces British tow balls, German tow balls, Dutch tow balls, chain tow balls, and the electroplating process is also a very professional skill of our company.Our company can undertake packaging, electroplating, and other services.

Bolt

Our company can produce most of the bolts on the market, including 1. Hexagon head bolt: one of the most common types of bolts, the head is hexagonal, making it easy to tighten with a wrench.

Round head bolt: The head is round and is usually used where the head needs to be hidden.

2. T-bolt: One end is the bolt head and the other end is a straight rod. It is usually used in conjunction with grooved rails.

3. U-shaped bolts: U-shaped, mainly used to fix pipes, cables, etc.

4. Expansion bolts: specially used for fastening hard materials such as concrete or brick walls.

5. Square head bolt: The head is square and suitable for some specific fastening applications.

Nut

“A nut is a part used for threaded connections, commonly paired with bolts. By rotating, it can be securely fastened in mechanical structures. They are typically hexagonal to facilitate rotation and tightening with wrenches or sockets. Nuts come in various types, including standard hex nuts, square nuts, locking nuts, etc., and are widely used in fields such as construction, mechanical manufacturing, the automotive industry, and more.

In addition to the common hex nuts, there are also specially designed nuts for specific applications or for added safety and performance. Here are a few common nut types:

Square Nuts (Square Nuts): Have a square shape and are typically used where a larger contact area is required or easier to turn by hand.

Locking nuts: Designed with a special structure that allows them to provide higher resistance to loosening after installation, such as nuts with spring blades or locking nuts made of special materials.

Round nut: It has a round shape and is usually used in specially designed mechanical structures or when rotational installation is required.

Aircraft Nut: A high-strength nut used in aircraft and other demanding applications to ensure a secure bolted connection.

Countersunk Head Nut: A nut with a countersunk head design, typically used where a flat surface is required or where the height of the nut protrusion is limited.

Flange Nut: A design with a flange used in applications where a nut is required to be secured to a surface, such as on sheet metal or plastic parts. Each of these different types of nuts has its own unique design and purpose, and choosing the right nut for a specific application can ensure a secure installation and long-term reliability.

Contacts

Location

119CHUANGXIN EAST ROAD, XIALIN INDUSTRY ZONE, TANGXIA TOWN, RUIAN CITY, CHINA

phone

+86 15381572265